TYPICAL INSTALLATION

A typical installation starts with a free roof estimate by Roofcan. Through a series of questions, along with our site visit, we can determine together, the best option for you. We may recommend an infra-red thermal scan of the roof to better determine the amount and location of any wet insulation. Test cuts into the existing roof will confirm the makeup and condition.

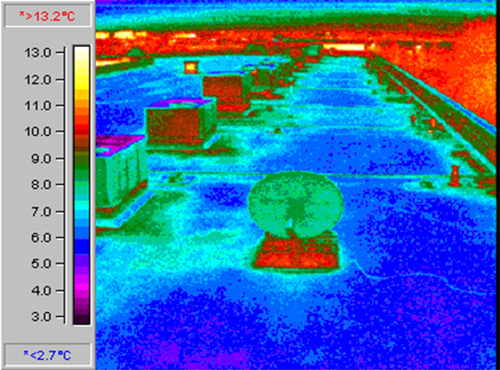

An infra-red thermal scan of the roof to better determine wet insulation. |

Roof preparation may include vacuuming off or power sweeping the existing loose gravel. |

Complete removal of the existing roof when necessary, or proper preparation to retrofit a new roof. |

Deck replacement or repairs where necessary. |

> Installation of vapour barrier and insulation over steel deck. |

> Mechanically fasten insulation to deck to prevent wind uplift (most common practice in today's roofing systems). |

Installation of membrane over insulation. Above: Base sheet mopped in with hot asphalt).

|

Installation of top coat such as Granular Cap Sheet (photo above). This granular surface acts like gravel to protect from the ultraviolet rays of the sun), or gravel (in the case of a BUR or inverted roof). Inverted roofs have the membrane directly over the deck with the insulation and gravel over top of it. |

Lowering of existing roofing debris is often done with a chute to prevent damage and contain dust. |

Metal installation to finish off the job providing an esthetic trim to the roof profile. |

Typical completed roof (this one with granular surfaced modified bitumen membrane) has several advantages including that nothing is visually hidden under gravel. Roof problems are more visible. The granular surface protects the membrane from ultraviolet rays of the sun and comes in different colours. Lightweight and flexible membrane remains elastic with expansion and contraction. |

Typical completed roof |

|